Matters needing attention when dyeing with high temperature and high pressure Dyeing Machine

2022-10-29

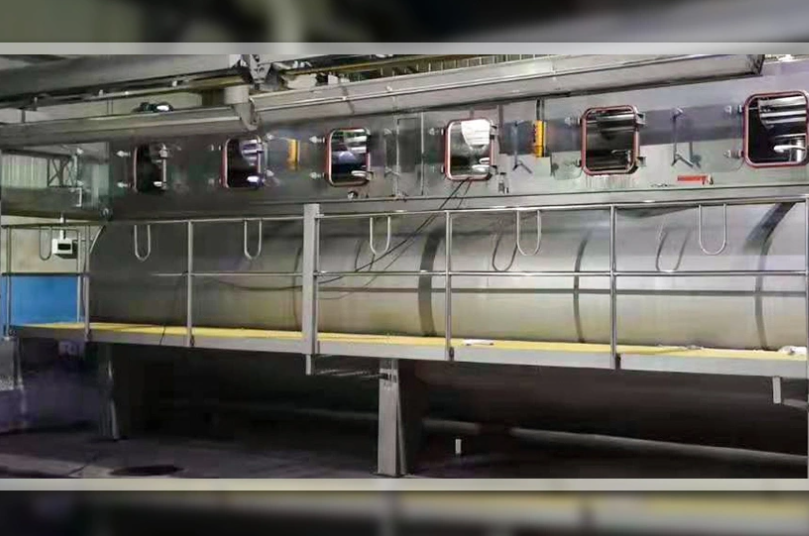

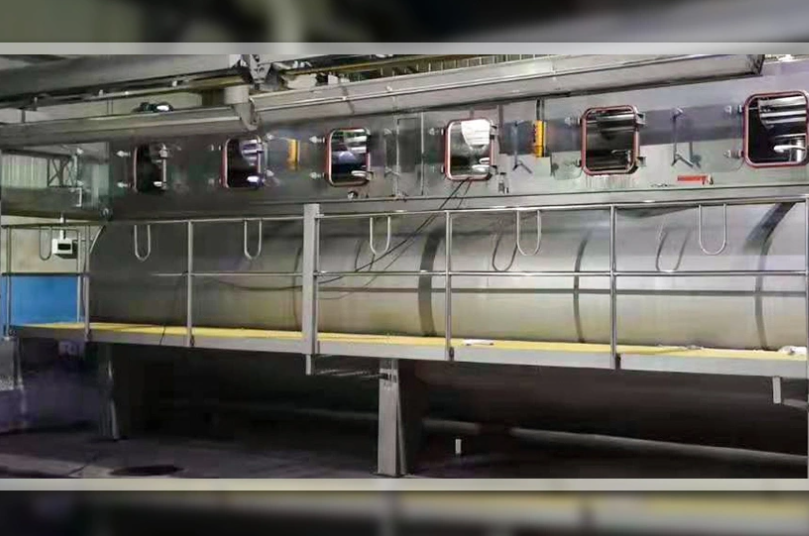

Matters needing attention when dyeing with high temperature and high pressure Dyeing Machine: In order to avoid defects such as colored flowers, stains, stains, etc. caused by improper process operation and poor operation, the following matters should be paid attention to when dyeing with high temperature and high pressure Beam Dyeing Machine: 1. Selection of dyes When dyeing, try to choose varieties with good diffusivity and levelness, and choose dyes with similar dyeing performance when combining colors. 2. Reduction cleaning Reduction cleaning is an important part of removing floating color. After reductive cleaning, the color is slightly lighter. At the same time, the rubbing fastness and the light fastness were improved.

3. Prevention of tar spot The so-called tar spot is a viscous substance formed in the dye liquor, and the main components are dye dispersant and polyester oligomer. When polyester oligomer is polyester polycondensation, it will seep out from the fiber and flow into the dye liquor and adhere to the fiber surface during the high temperature and long-term dyeing process. Measures to prevent tar spots include: (1) Strengthen the pretreatment of fabrics. (2) Improve the dyeing bath ratio. (3) Apply high temperature and high pressure dispersant. (4) High temperature drainage is adopted to avoid the crystallization of dyestuff after cooling. (5) Shorten the cleaning cycle of Fabric Dyeing Machine equipment. 4. When preparing the dye solution, the dye should be made into a slurry with a small amount of cold water first, and then diluted with room temperature water. Note that the temperature of the diluted water should not be too high, higher than 60 degrees, the dispersion dyeing quilt will be damaged, and Coagulation, in addition to the above modulation, the dye can also be modulated by the dusting method.